Production of Polyester RTM Machine…

PROPERTIES OF POLYESTER RTM MACHINE

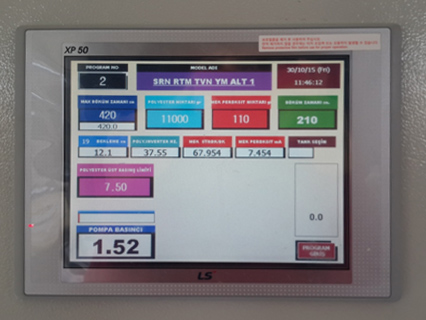

1.Touchscreen Control

Sensitive touchscreen

2.Barcode Identification

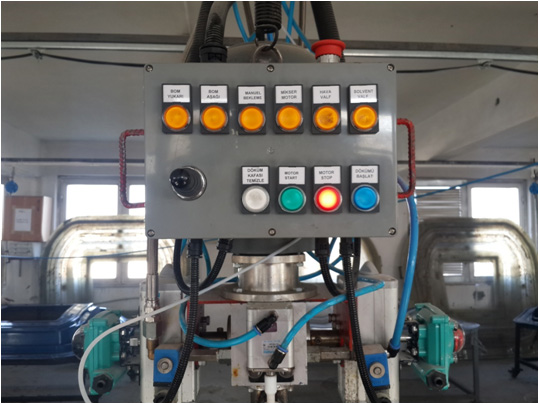

Barcode identification enables the machine to identify the production formulas of the products recorded in the machine through a barcode to be stuck to the mold. It is enough for the operator to press “Casting Start” (Döküm Start) button after scanning the barcode on the mold. It is possible to easily prevent the errors of the operator applying this identification process.

The FIRST Polyester RTM Machine of Turkey

Capacity of POLTRANS T1 RTM MACHINE…

Production Capacity: 200 g/min – 10,000 g/min

Mek Rate Accuracy: Adjustment interval is 0.5% - 3%

Total Power: 18 kw

Memory Capacity: 100 programs

Touchscreen Control

Sensitive touchscreen.

Barcode Identification

Barcode identification enables the machine to identify the production formulas of the products recorded in the machine through a barcode to be stuck to the mold. It is enough for the operator to press “Casting Start” (Döküm Start) button after scanning the barcode on the mold. It is possible to easily prevent the errors of the operator applying this identification process

Control of Internal Pressure in the Mold

Polyester pressure in the mold is controlled by means of the electronic pressure sensors with high precision which is on the pressure line of Poltrans T1, during pressing process. If the pressure interval determined is not followed, Poltrans T1 automatically switches to standby mode and gives warning with signal. When the required pressure values are obtained, the operation resumes.

ADVANTAGES

Any swelling in the mold is hindered.

Local heating of the product is prevented.

Thickness of the product is kept at standard measures.

Damage of the mold is prevented.

Automatic Filling

Amounts of the raw materials (polyester, mek, solvent) in the tanks are shown with the electronic level indicators on Poltrans T1. Filling process is performed at a level predefined by the operator.

Automatic Heating

There are electric resistances run through the computer control on the tanks of Poltrans T1. Operator can identify the temperature value of the raw material from his control panel.

ADVANTAGES

Stabile temperature of raw material

Standard press time by keeping the temperature values constant

Standard number of products despite the varying temperatures of raw materials

Automatic Mixers

Each polyester tank of Poltrans T1 has a spiral mixer which runs automatically during heating. Moreover, the operator can run it manually at his will.

ADVANTAGES

Heat of homogeneous raw material

Distribution of homogeneous cobalt

Stabilized viscosity of raw material

Properties of Cast Air Pump…

Cast air pump of Poltrans T1 is completely operated by a computer. Its mixer is made of spiral aluminum.

Advantages

The mixture of mek-polyester-pigment is achieved at a perfect homogeneity.

Cleaning is possible with a single-button.

There is a storage battery to clean the air pump in case of the electricity cuts.

It is equipped with an easily accessible electronic keypad.

It can twizzle 300°. Thus, the casting process using various surrounding molds is allowed.

2 RAW MATERIAL TANKS

Poltrans T1 has two raw material tanks that operate independently.

Advantages

Simultaneous operation in case of two different polyester resins

Two color alternatives for polyester

Useful valves for discharge

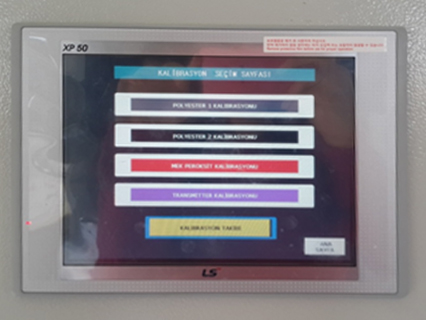

Calibration Program

Poltrans T1 is equipped with the software of a calibration program.

Advantages

Easy calibration

Raw materials having different specific weights are pressed using gram precision

Automatic Cleaning of Air Pump

Poltrans T1 warns the operator through warning statements (in writing) and vocally after casting is completed. It then gives command to clean the air pump. Operator separates the molds from the machine and pushes “Air Pump Cleaning” button to clean the air pump automatically by means of the program.

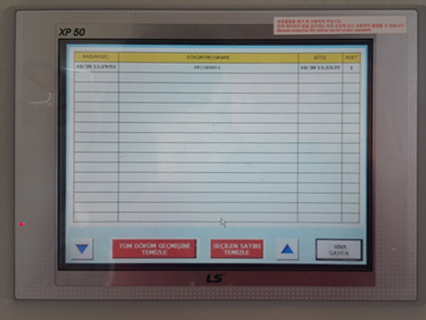

Production Tracking

It is possible to track the whole production retroactively from “production analysis” page in the programs of Poltrans T1.

Advantages

Traceability.

Controlling the work of the staff

Controlling casting times.

Controlling the use of raw materials.

ACCURATE PRODUCTION

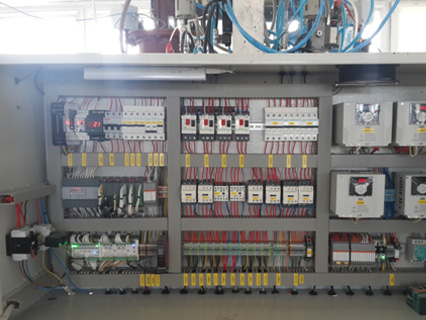

Pump, motor, sensor and drivers of Poltrans T1 having high quality ensure every product to be standard.

The mixture of mek-polyester-pigment can be adjusted precisely within the interval of 0.5%-3%.

The quantity of mek pressed with the quality pumps and drivers has gram precision.

The quantity of solvent to be used in washing can be changed easily via the program.

HIGH OPERATING SAFETY

Use of non-flammable and non-inflammable solvent

Tank pressures controlled by computer

Safety valves

Breakdown & hazard warning programs

Uninterruptible Power Supply (Optional)

In case of electric cuts, uninterruptible power supply enables the completion of the casting process by supplying power until the generator is activated in the facilities that have generator

Joystick-Controlled Movement (Optional)

Poltrans T1 can be moved in the production facility using the joysticks on the air pump.

PLEASE

CONTACT US

TO RECEIVE OFFER AND ASK ANY QUESTIONS

This post is also available in: Turkish