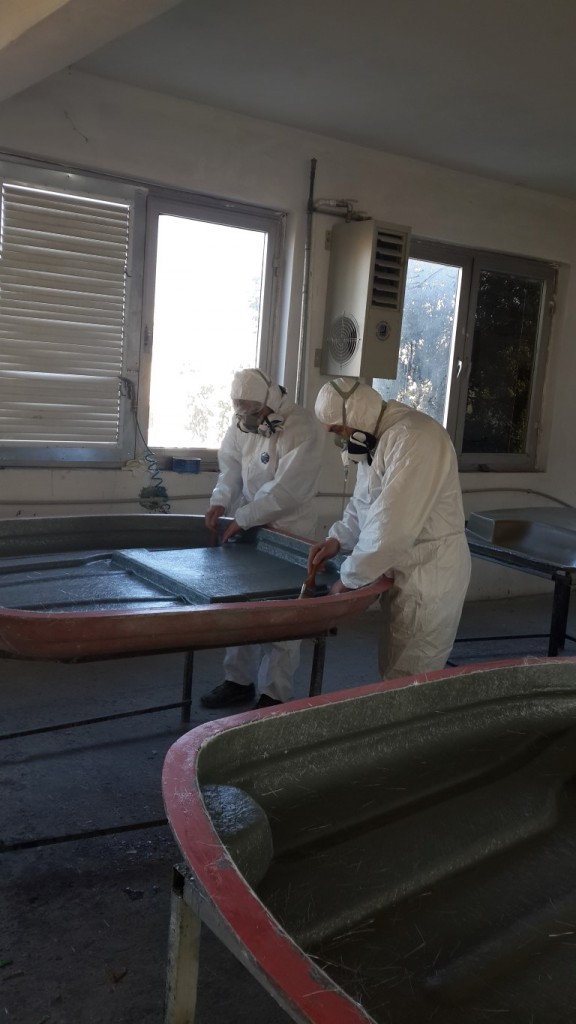

Hand Lay-Up Method - Low Capital Cost

Hand lay-up is the oldest and most common open-moulding method used in the production of glass- reinforced plastics. In this method, glass fibre reinforcements are placed by hand in a mould and polyester resin is applied with a brush or roller.

Advantages of Hand Lay-Up Method

• Low capital cost

• No dimensional limitations

• Design flexibility

• Possibility of increasing the strength of particular areas

Disadvantages of Hand Lay-Up Method

• Low production rate

• One side is smooth but the other side is rough

• Production quality depends on individual dexterity

• Styrene emmision

In our company, hand lay-up products which are suitable for all kinds of industries and needs, are produced by our expert staff from design stage to production stage.

What Do We Produce Using Hand Lay-Up Method?

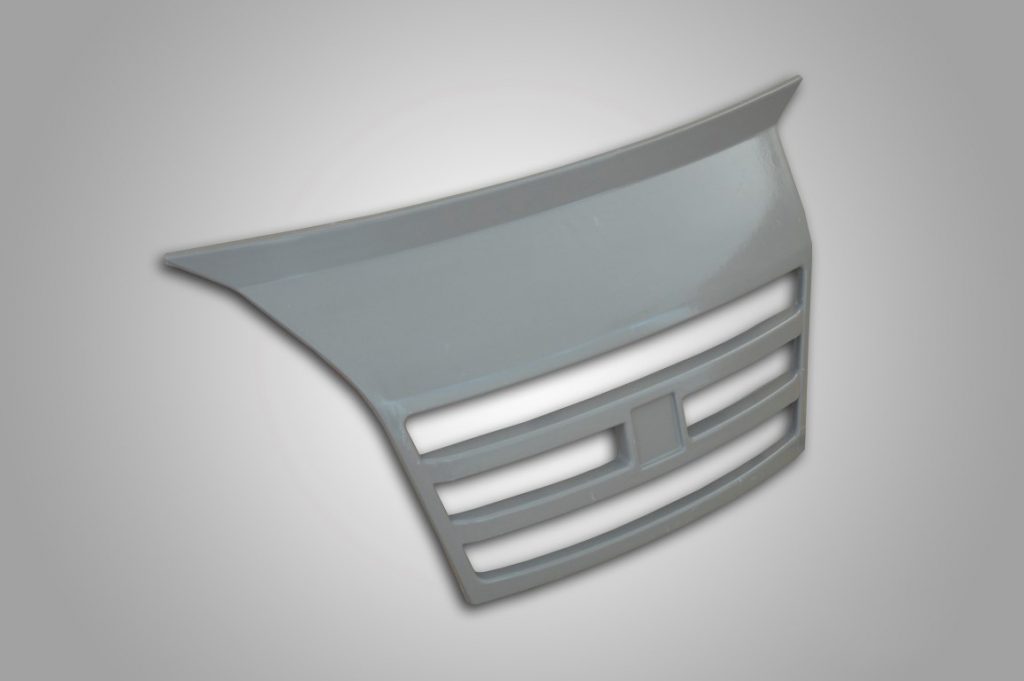

Automotive Industry

• Bumpers

• Headlamp Mouldings

• Boot Lids

• Blinds

• Mud Flaps

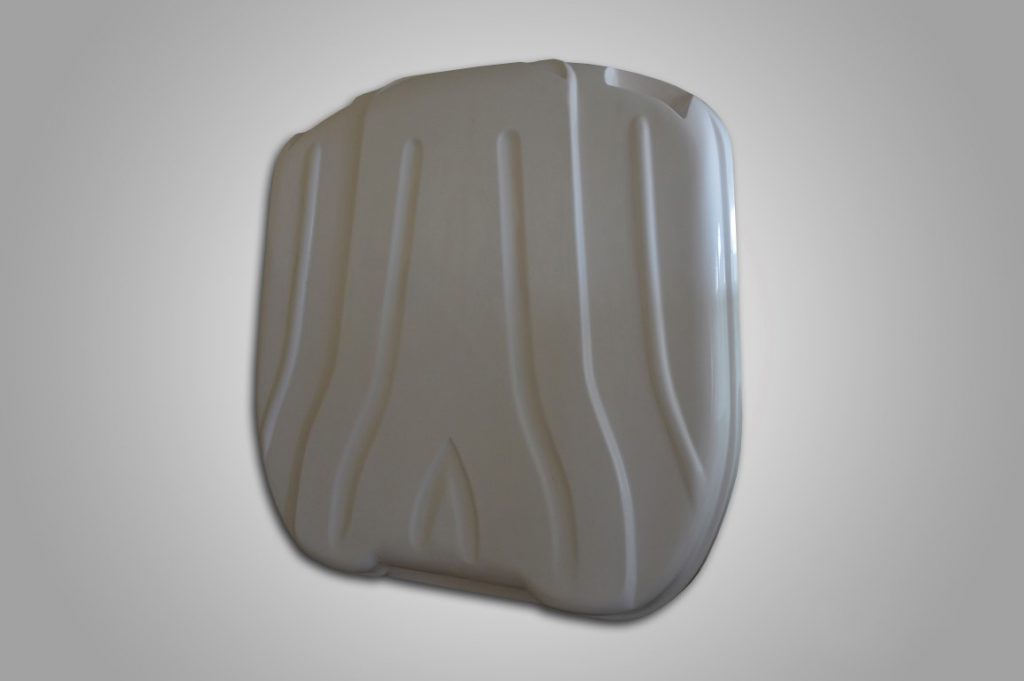

Agriculture Industry

• Tractor Hoods

• Ceiling of Safety Cabs

• Interior Ceiling of Safety Cabs

• Irrigation Tanks

• Agricultural Spraying Tanks

• Olive Storage Bins

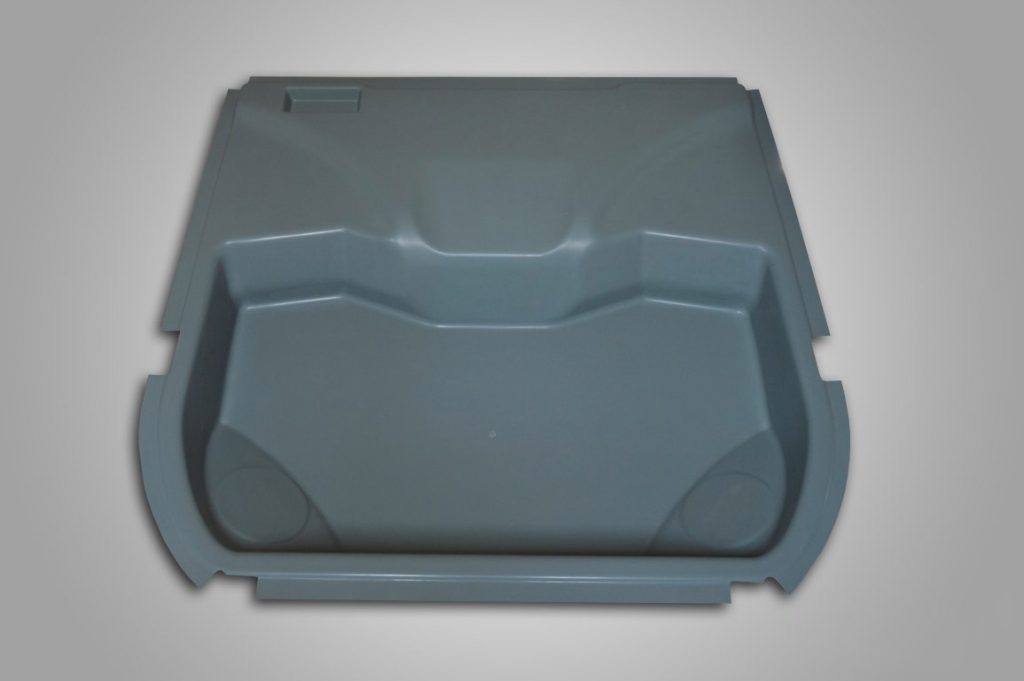

Heavy Construction Equipment

• Construction Machine Hoods

• Ceiling of Safety Cabs

• Interior Ceiling of Safety Cabs

• Mud Flaps

This post is also available in: Turkish