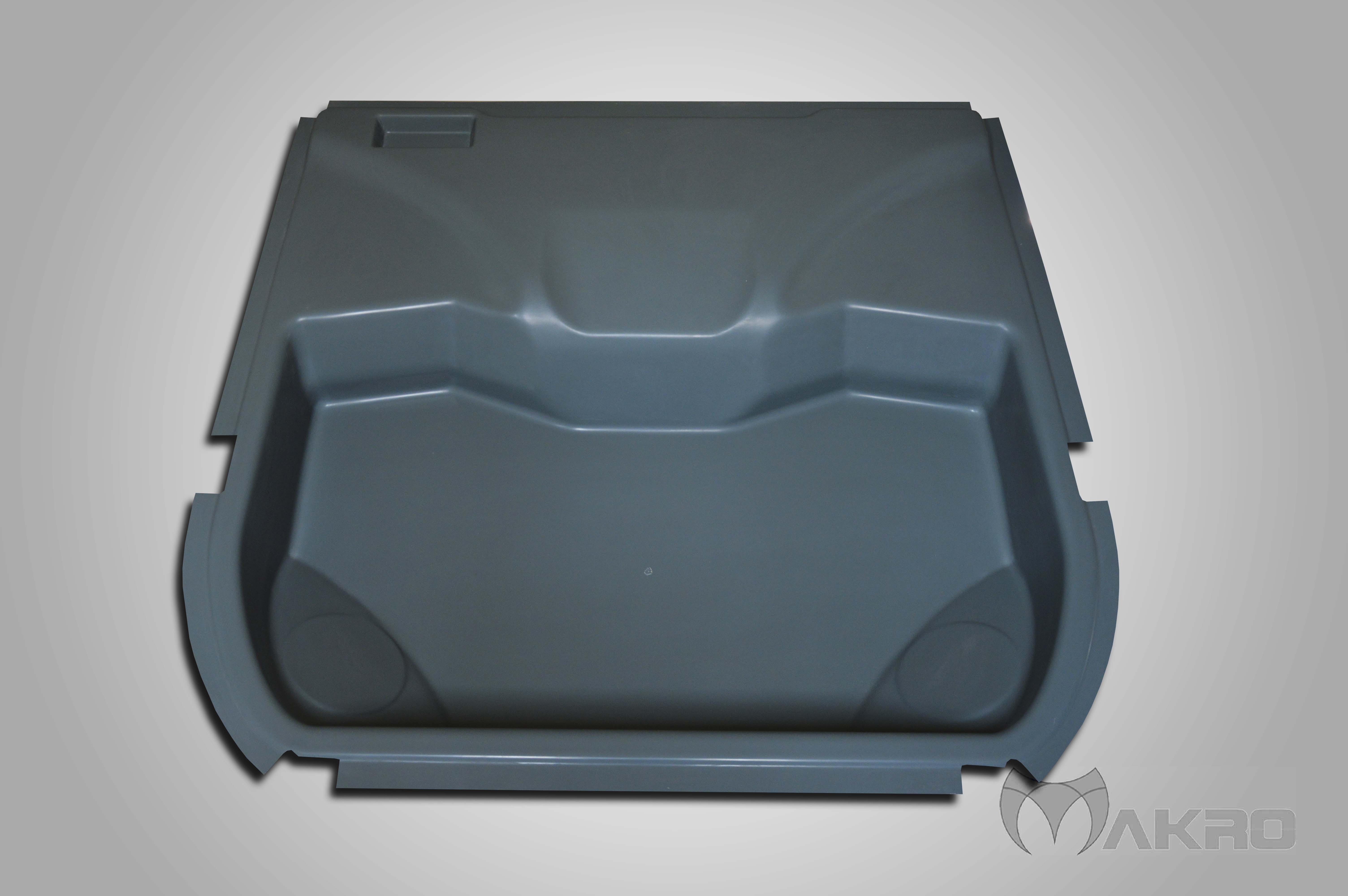

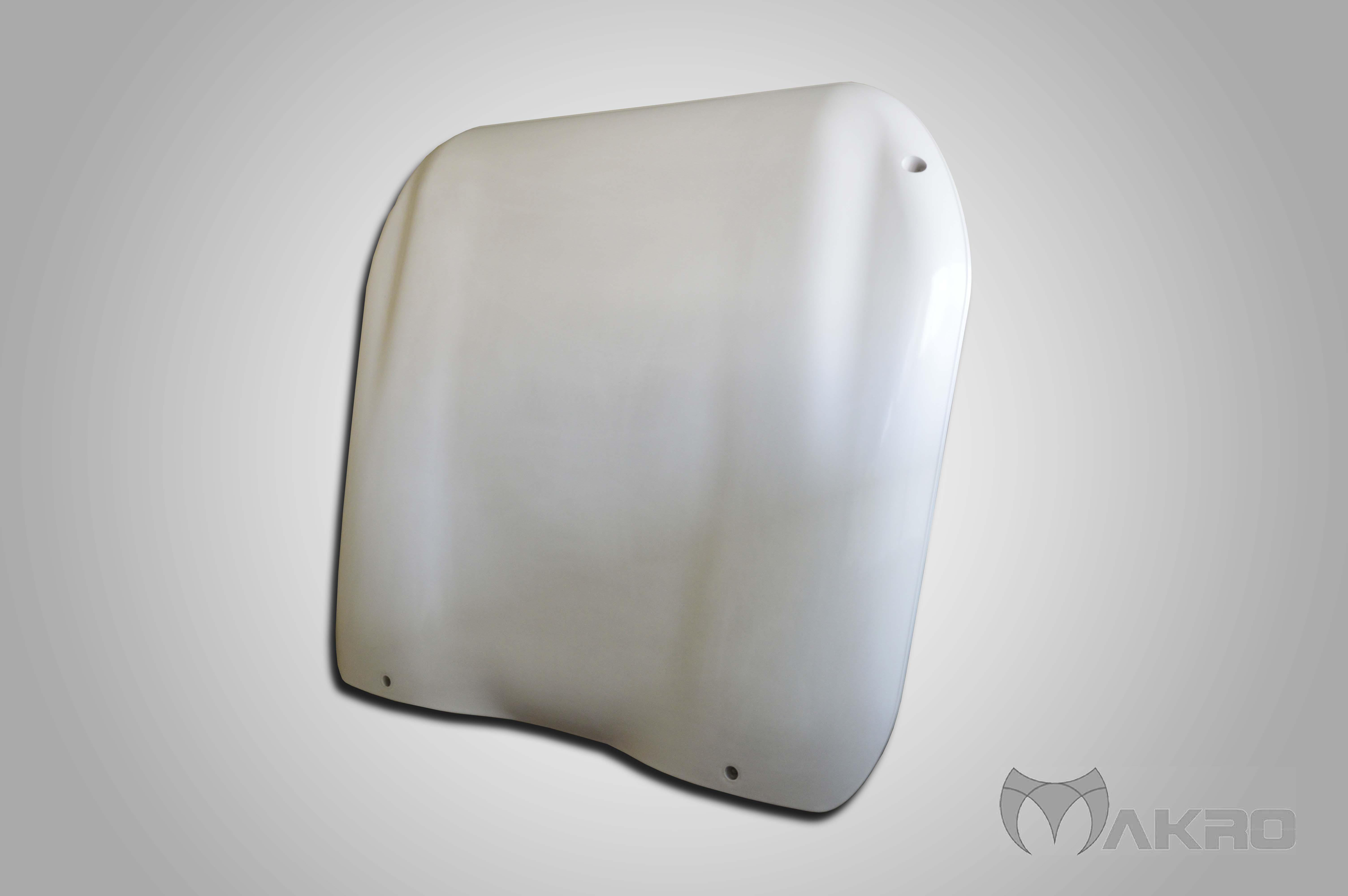

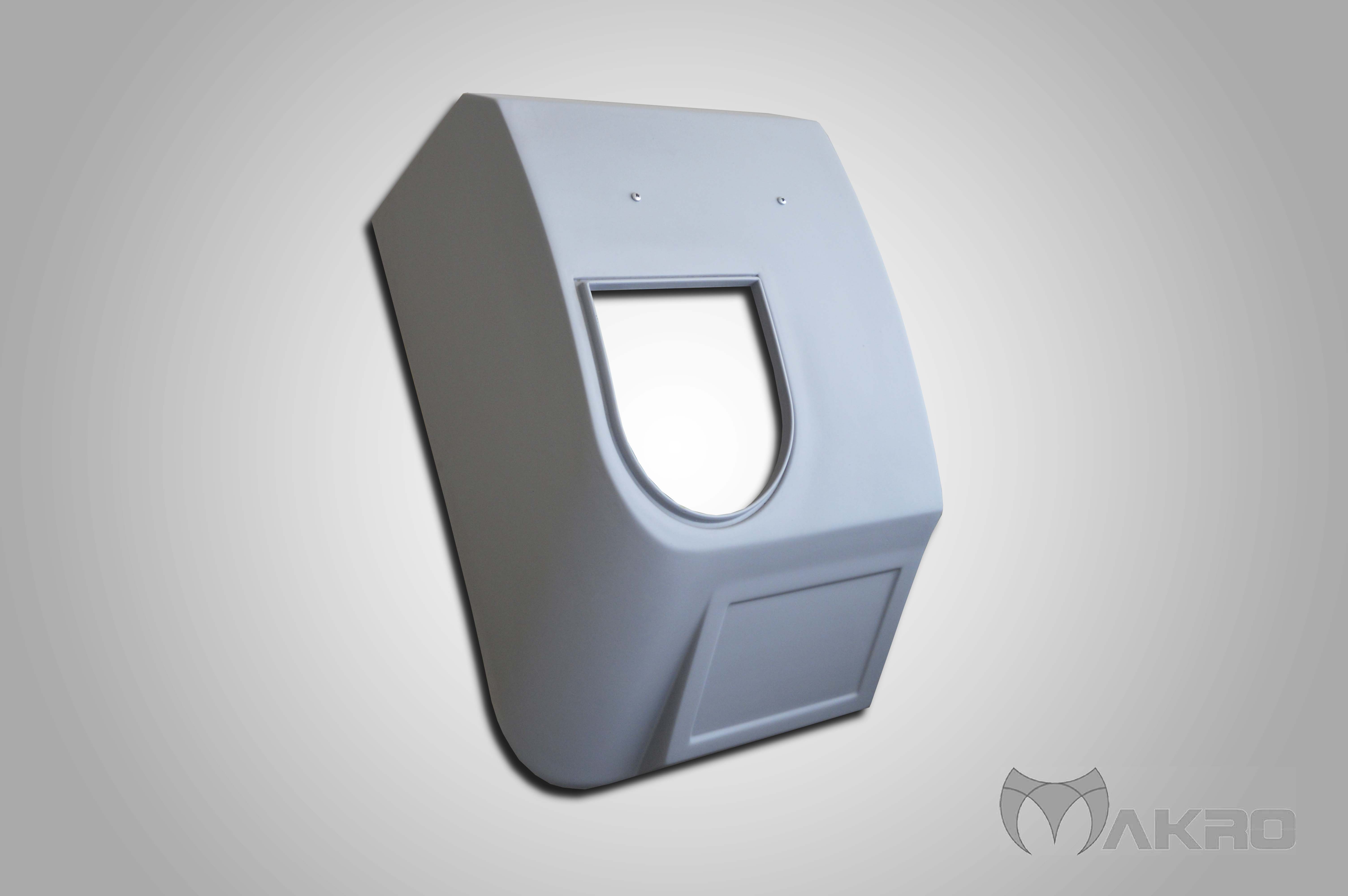

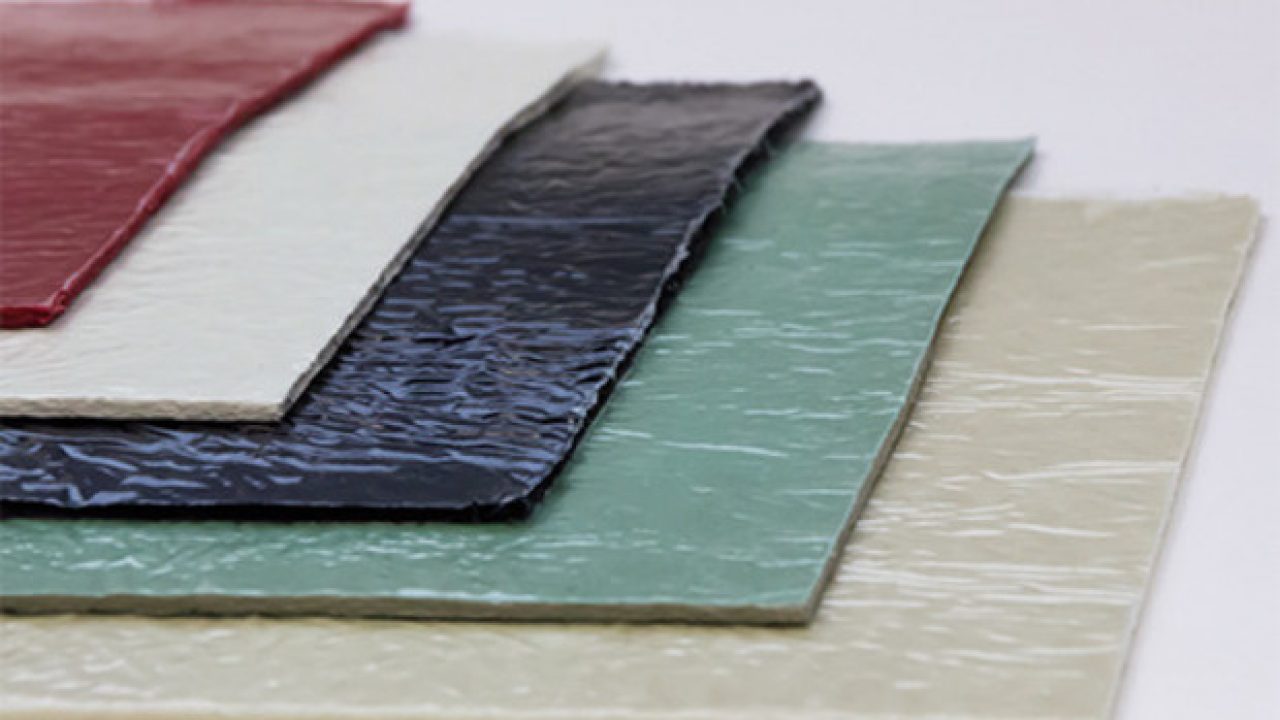

Sheet Moulding Compound - Excellent Surface Quality

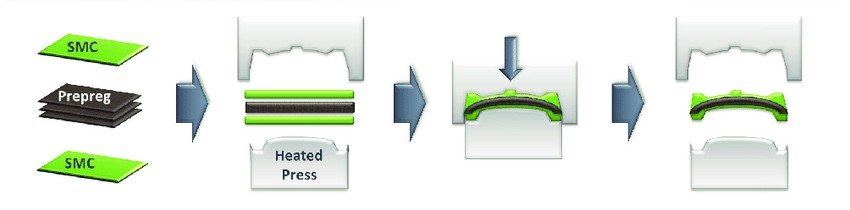

Sheet moulding compound (SMC) is an uncured thermoset compound produced in sheet form, which is ready to mould.This material, which primarily consists of a thermosetting resin, mineral fillers and glass fibre reinforcement, is formed into products by using compression moulding.

In this method , sheet moulding compound is placed onto the heated female mould, then the heated male mould is closed, forcing the SMC into the mould cavities. Consistent application of heat and pressure causes the SMC to soften and properly fill every part of the mould. Once the SMC has fully cured and hardened, the mould is opened and the molded product removed.

Advantages of SMC

• Mass production and efficiency

• Excellent surface quality

• Design flexibility

• Excellent temperature and fire resistance

• Low manpower requirements

• Reduced industrial waste

Disadvantages of SMC

• Dimensional limitations

This post is also available in: Turkish