Resin Transfer Moulding - Standardized Product Quality

Female and male volume moulds are used in this method. The glass fibre reinforcement is laid into the mould which is then closed and polyester resin is injected into the mould. When the resin has set the mould is opened and the finished product removed.

RTM is one of the best methods for mass production of composite parts. It is primarily used to mould components with large surface areas, complex shapes and smooth finishes.

Advantages of Resin Transfer Molding

• Standardized quality product

• High production rate

• Products with two smooth surfaces

• High impact resistance

• No dimensional limitations

• Design flexibility

• Low styrene emission

Disadvantages of Resin Transfer Molding

• High capital cost

We combined our experience in RTM with up-to-date technology.You dream it up, we design it and produce it.

What do we produce with RTM?

Automotive Industry

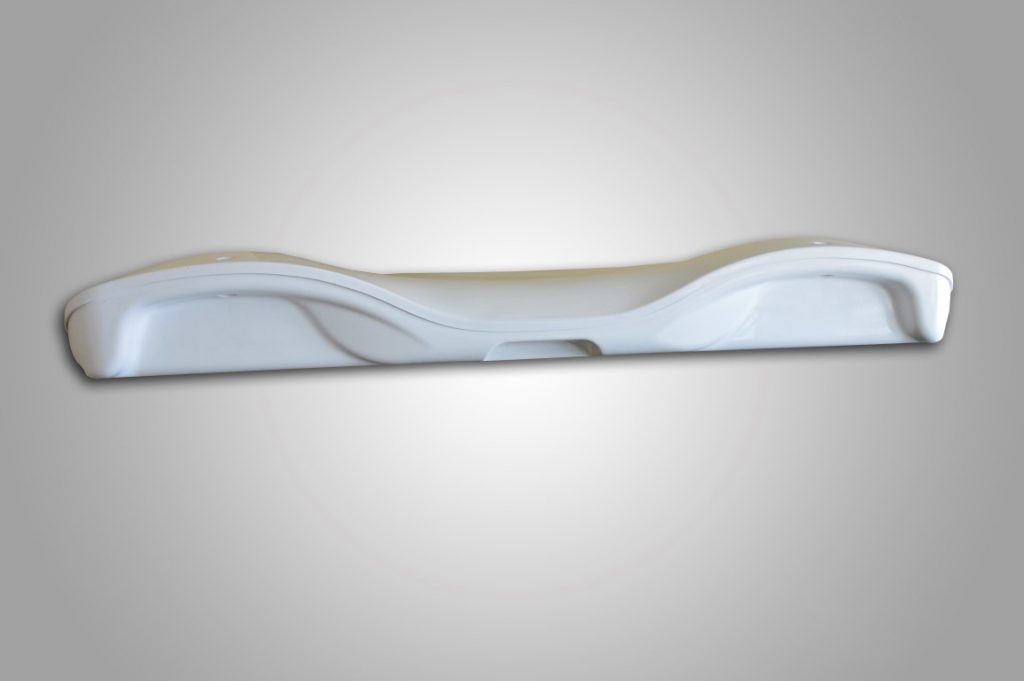

• Bumpers

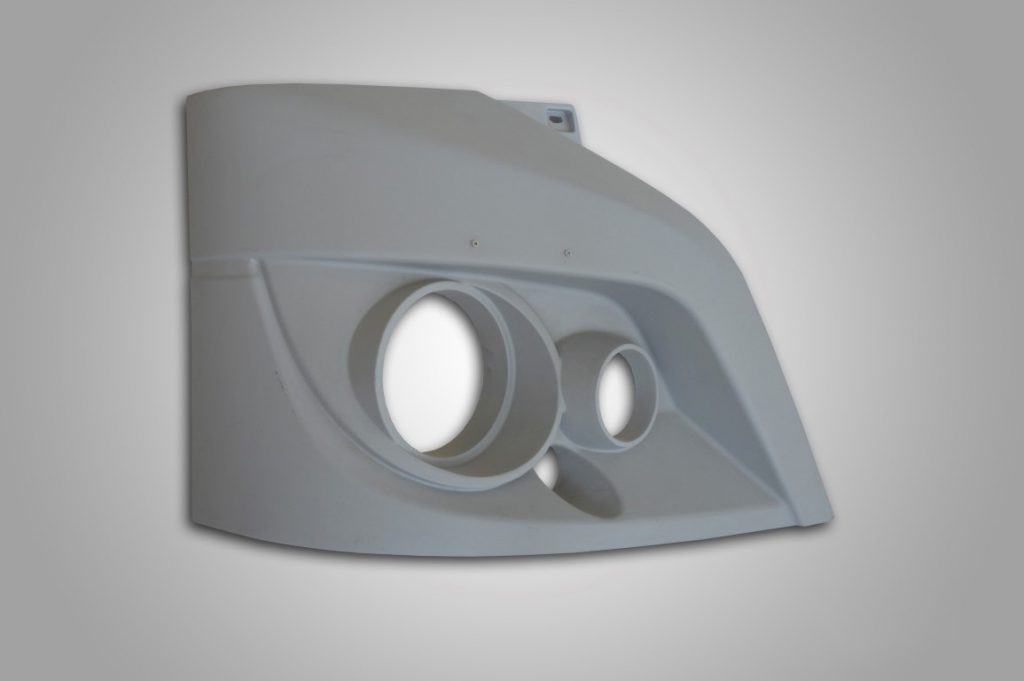

• Headlamp Mouldings

• Boot Lids

• Blinds

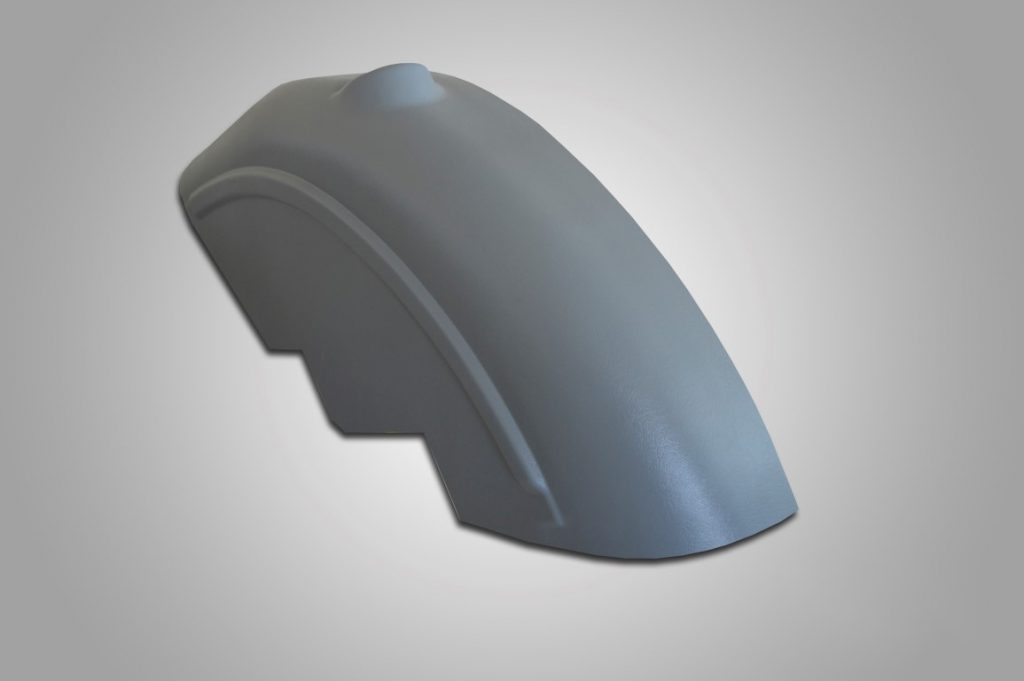

• Mud Flaps

Agriculture Industry

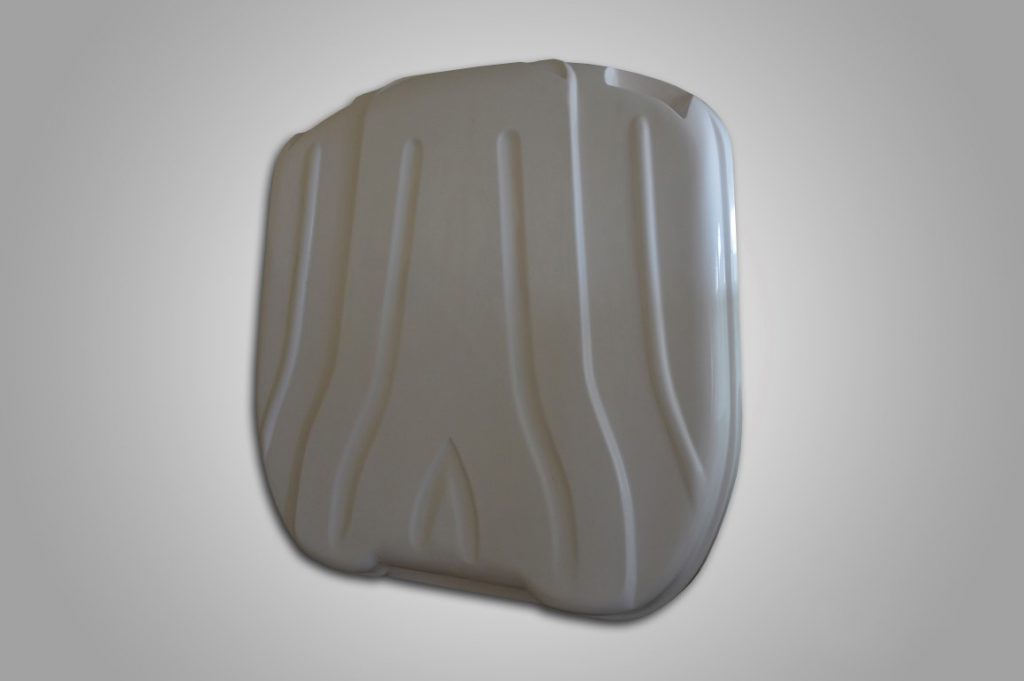

• Tractor Hoods

• Ceiling of Safety Cabs

• Interior Ceiling of Safety Cabs

• Irrigation Tanks

• Agricultural Spraying Tanks

• Olive Storage Bins

Heavy Equipment

• Construction Machine Hoods

• Ceiling of Safety Cabs

• Interior Ceiling of Safety Cabs

• Mud Flaps

This post is also available in: Turkish